In the intricate world of modern construction and manufacturing, the integrity of any structure often hinges on its most fundamental connections. Among these, the corner joint—a seemingly simple yet critically important connector—plays a pivotal role in ensuring stability, durability, and precision across countless applications. From towering curtain walls to elegant furniture and robust industrial frames, the performance of these connectors directly influences the longevity and safety of the final product. This article explores the multifaceted world of corner joints, examining their materials, functionalities, and applications, while underscoring the specialized expertise required for their production.

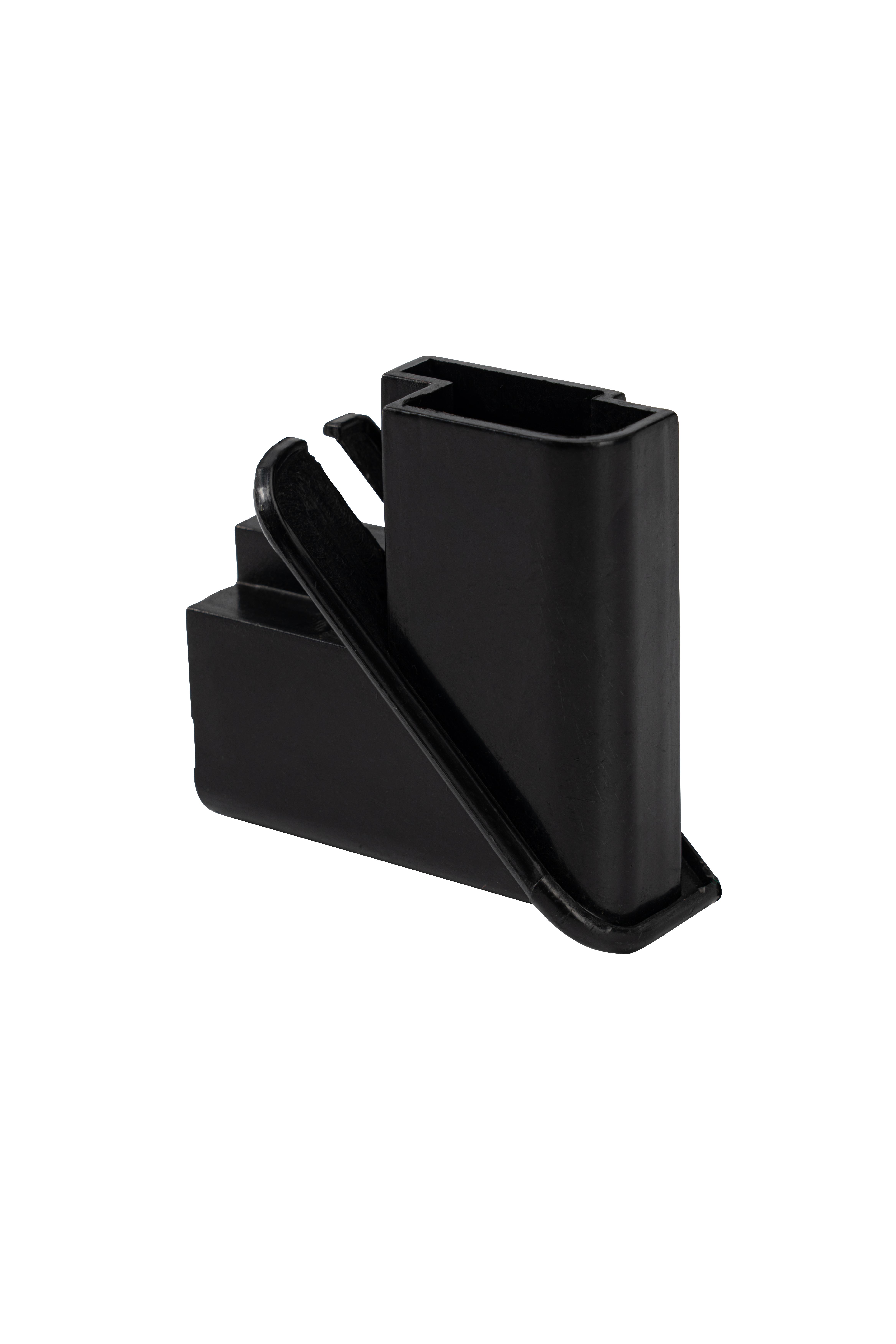

A corner joint, essentially a connector designed to join two components at an angle—most commonly 90 degrees—serves as the linchpin of structural integrity. Its primary function is to transfer load, resist shear and tensile forces, and maintain dimensional accuracy at intersections. While the basic concept is straightforward, the engineering behind an effective corner connector involves sophisticated considerations of material science, stress distribution, and environmental resilience.

Materials Defining Performance

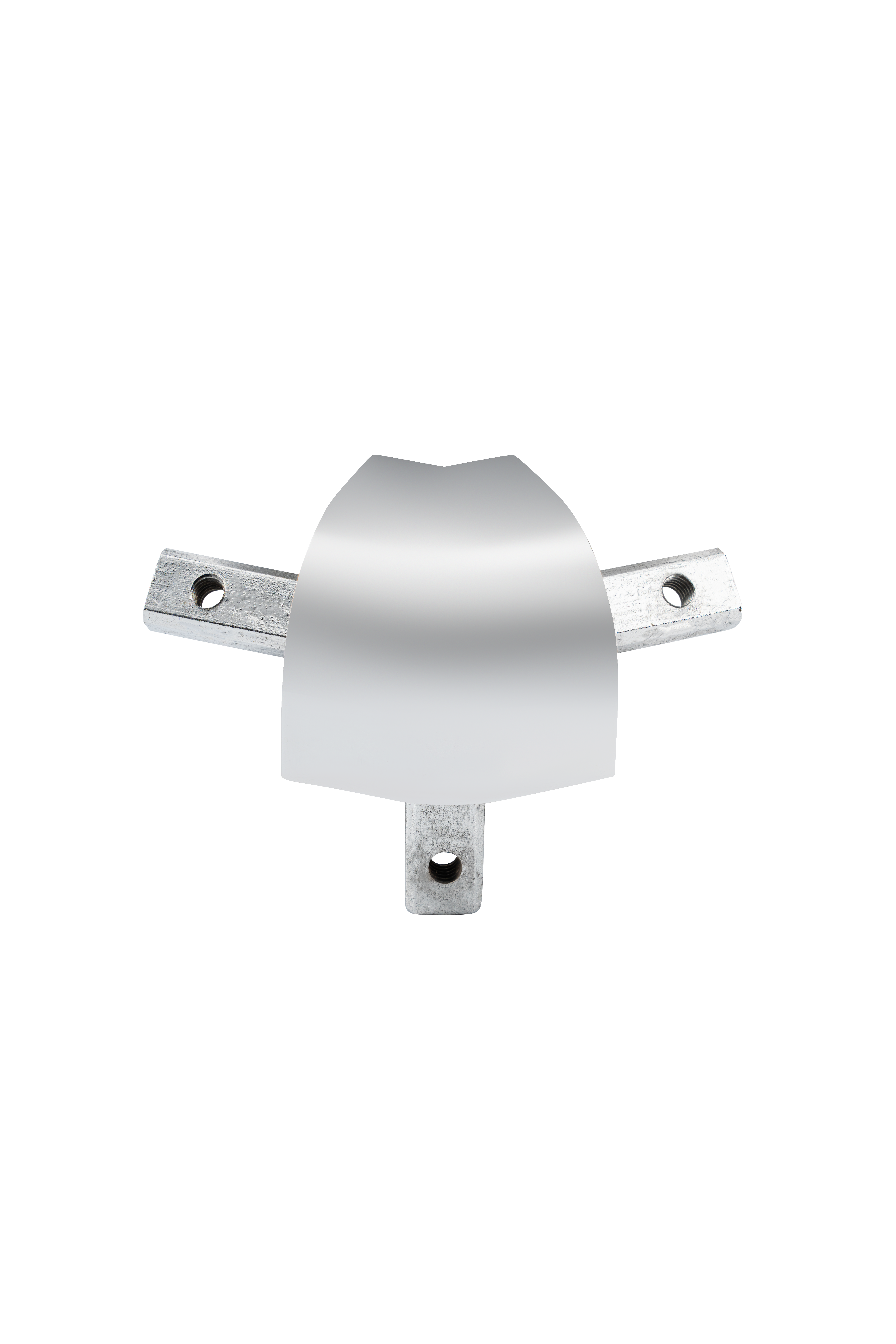

The selection of material for a corner joint is dictated by the demands of its application. Steel connectors remain the standard for heavy-duty structural applications, offering unparalleled strength and load-bearing capacity. Typically treated with galvanization or powder coating for corrosion resistance, these connectors are indispensable in construction frameworks, industrial shelving, and infrastructure projects where maximum durability is non-negotiable.

For applications where weight reduction is crucial without compromising strength, aluminum corner joints provide an optimal solution. Aluminum connectors combine a favorable strength-to-weight ratio with natural corrosion resistance, making them ideal for curtain wall systems, window and door frames, transportation equipment, and architectural features. The versatility of aluminum also allows for precision extrusion and machining, enabling complex connector profiles tailored to specific design requirements.

In specialized environments, stainless steel connectors offer exceptional performance where hygiene, chemical resistance, or extreme environmental conditions are factors. These are commonly specified in food processing facilities, marine installations, and architectural applications demanding both aesthetic appeal and longevity.

Functional Diversity in Connector Design

Corner joints evolve far beyond simple L-shaped brackets. The market offers a sophisticated array of designs, each engineered for specific functions:

Standard Angle Brackets: The workhorse of the industry, providing basic reinforcement for furniture, light framing, and shelving.

Reinforced Gusset Connectors: Featuring added triangular supports or ribbing to handle significantly higher loads in structural frameworks and trusses.

Adjustable Corner Joints: Incorporating slotted holes or modular designs to accommodate tolerances and allow for alignment adjustments during installation, crucial in custom architectural projects.

Concealed Connectors: Designed to be invisible upon project completion, these are essential for high-end furniture, cabinetry, and architectural woodworking where aesthetics are paramount.

Specialized Curtain Wall Connectors: Engineered to manage structural loads, thermal expansion, and water management in modern building facades.

UHIT‘s Professional Manufacturing Excellence

With nearly two decades of specialized experience, UHIT has established itself as a leading producer of precision corner joints and related architectural connectors. Located in Foshan, Guangdong—the heart of China's manufacturing industry—we leverage advanced production technology and deep material expertise to deliver connectors that meet the most stringent international standards.

Our manufacturing philosophy is built on three core pillars:

Material Precision: We source and process high-grade aluminum alloys, steels, and stainless steels, ensuring each connector offers consistent mechanical properties and longevity.

Engineering Excellence: Our in-house engineering team collaborates with clients to develop custom connector solutions, optimizing designs for specific load requirements, assembly methods, and aesthetic integration.

Quality Assurance: From raw material inspection to final finishing—including anodizing, powder coating, or mechanical polishing—every production stage undergoes rigorous quality control.

UHIT serve a diverse global clientele, providing connectors for: Curtain walls, windows, doors, and structural glazing. Our capability to handle both standardized high-volume orders and complex custom projects makes us a reliable partner for contractors, fabricators, and architects worldwide.

The humble corner joint is, in reality, a critical component that bridges design ambition with structural reality. Its correct selection and manufacture can mean the difference between a good project and a great one. We invite architects, engineers, project managers, and procurement specialists to consult with our technical team on your next project. Whether you require a standard connector or a custom-engineered solution, our expertise is at your service. For detailed specifications, technical drawings, or project consultations, please contact us to discover how our precision connectors can form the foundation of your success.