We often admire windows for their frames—sleek aluminum profiles in modern finishes. Yet, the true determinants of a window’s comfort, efficiency, and longevity are the hidden, flexible components that form its environmental seal. These materials operate silently, bridging gaps, absorbing movements, and standing resilient against the elements. Their performance is a sophisticated interplay of material science, mechanical design, and enduring elasticity.

At the heart of operable sashes and doors lie the flexible seals, commonly called weatherstrips. These are primarily elastomeric extrusions, crafted from materials like EPDM (Ethylene Propylene Diene Monomer), TPV (Thermoplastic Vulcanizate), or silicone. Their role is multifaceted: to block air infiltration, repel water, dampen sound, and sometimes to provide a soft-close cushioning effect. The design of the seal’s profile—whether a simple bulb or a complex multi-chambered structure with hollow sections for enhanced compression—is critical. It must maintain consistent pressure against the frame and sash across varying temperatures, resisting permanent deformation or “compression set.” A high-quality sealing strip will recover its shape for years, ensuring the window’s initial performance metrics for thermal insulation and weathertightness are not just a promise at installation but a sustained reality.

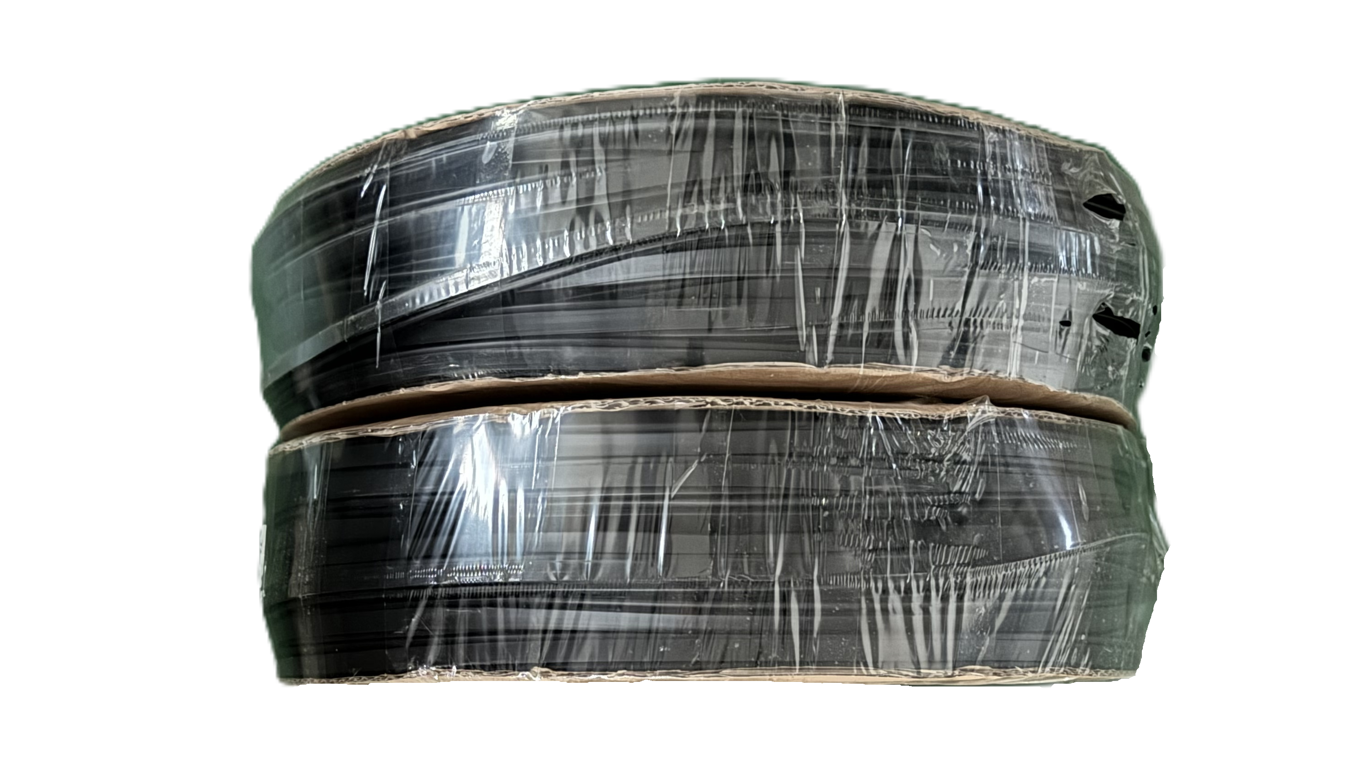

For sliding windows and doors, a different type of barrier is essential. Here, dense filament brush seals, often referred to as pile seals, come into play. Comprising thousands of fine, stiff filaments (typically polypropylene or nylon) anchored into a carrier strip, these brushes create a dynamic, low-friction barrier. As a sash slides, the filaments conform to microscopic irregularities in the track and the opposing frame. Their primary victory is against dust, fine particles, and wind-driven rain, while also offering a degree of resistance to air flow. The effectiveness of a pile seal depends on filament density, length, and resilience. In superior systems, these brush seals work in tandem with primary elastomeric seals, creating a multi-stage defense that makes sliding systems remarkably tight.

No discussion of window sealing is complete without acknowledging the adhesive that binds it all together: the sealant. Most visibly, it is used as glazing sealant—the durable, flexible bead that bonds the glass pane to the frame’s rebate, creating a watertight and structural connection. Silicone-based glazing sealants are renowned for their exceptional UV resistance, elasticity, and longevity, making them ideal for this exposed role. They accommodate the differential expansion between glass and aluminum, preventing stress fractures and moisture ingress. Similarly, sealants are indispensable at installation junctions—where the window frame meets the building structure. Here, they bridge the construction gap, compensating for tolerances and preventing air and water penetration directly into the wall assembly. The choice between silicone, polyurethane, or hybrid polymer sealants depends on specific requirements for adhesion, movement capability, and paintability.

The silent failure of these components is the leading cause of perceived window underperformance. A hardened, cracked sealing strip allows drafts and noise to enter. A worn-down brush seal admits dust and reduces smooth operation. A degraded glazing sealant can lead to leaks, fogging between glass panes, and even compromised glass retention. Therefore, selecting windows is as much about evaluating these flexible components as it is about the rigid frames. Look for seals made from reputed compounders, pile seals with high filament count and robust carriers, and sealants from trusted manufacturers with proven weatherability data.

In conclusion, the aluminum provides the form, but the seals provide the function. They are the dynamic interface between the static building envelope and the dynamic external environment. Investing in windows with advanced, durable sealing materials—the extruded strips, the brush piles, and the high-performance sealants—is an investment in lasting comfort, lower energy bills, and preserved structural integrity. They are, without exaggeration, the unsung guardians of our indoor environment.