The elegance of a frameless glass door lies in its minimalist transparency, creating seamless transitions between spaces. Yet, this aesthetic simplicity is achieved through a sophisticated array of specialized hardware—the door control system. These components work in concert to provide safe, controlled, and reliable operation, bearing the entire structural and functional load. Understanding the suite of floor springs, clamps, and locks is essential for specifying a system that is both beautiful and robust.

The cornerstone of many heavy-duty glass door systems is the floor spring, or door closer concealed in floor. This device is installed within the floor, completely hidden from view, making it the ideal solution for achieving a clean, uninterrupted aesthetic. It performs three critical functions: it serves as the bottom pivot point for the door, it controls the door's swinging speed (closing and latching), and most importantly, it holds the door open at a predetermined position (typically 90 or 105 degrees) through a reliable hold-open mechanism. High-grade floor springs are engineered for millions of cycles and are adjustable for closing force and speed to accommodate different door weights and environmental conditions like drafts. Their installation requires precise alignment and a solid subfloor, as they bear the door's entire dynamic load.

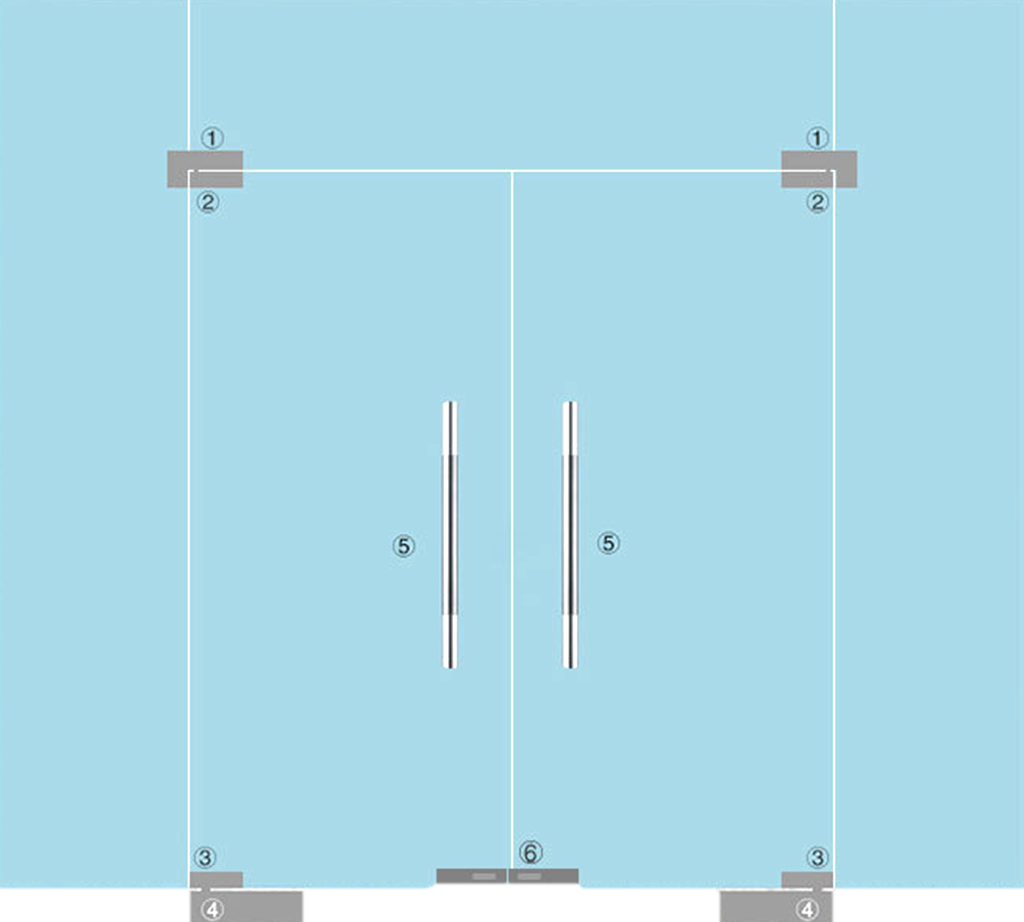

Complementing the floor spring at the top is the top pivot, or upper bearing assembly. For doors using a floor spring, the top pivot is often a simple, low-friction bearing housed in a top clamp or bracket, allowing the door to rotate smoothly around a vertical axis. In systems without a floor spring (e.g., some single-action doors), a heavy-duty top pivot or overhead closer takes on the role of supporting weight and controlling motion from above.

The hardware that physically grips the glass is categorized into clamps. The top clamp and bottom clamp are the primary fixtures securing the top and bottom edges of the glass panel. They are precision-machined from stainless steel or aluminum, lined with non-marking neoprene or EPDM gaskets to cushion the glass and ensure a firm, stress-free grip. The bottom clamp often integrates directly with the spindle of the floor spring. A corner clamp, also known as a 90-degree corner clamp or L-clamp, is used to join two glass panels at a right angle to create a corner entrance without a vertical post. Its design must distribute stress evenly across the glass edges.

For locking and security, the hardware options are diverse. A center lock (or mid-rail lock) is a common choice for glass doors. It is mounted at the meeting point of two doors or on a single door against the jamb, at waist height. When engaged, a bolt shoots horizontally into a strike plate. A floor lock is a discrete, flush-mounted locking mechanism installed in the floor. It engages with a receptor in the bottom of the door, providing security without visible hardware on the door face. For double doors, an astragal may be used—a vertical post attached to the active leaf that the inactive leaf closes against, often incorporating a flush bolt that descends from the inactive leaf into the floor.

The final interface with the user is the stainless steel handle or pull. Beyond aesthetics, its ergonomics and installation are critical. For glass doors, handles are typically mounted using through-bolts that pass through pre-drilled holes in the glass, secured on the opposite side. The quality of the stainless steel (e.g., 304 or 316 grade), the precision of the machining, and the comfort of the grip are key indicators of quality. These handles serve as the tactile point of contact and must inspire confidence.

Selecting and specifying this ecosystem requires a systems-thinking approach. Load ratings must be calculated based on door size, glass thickness, and usage frequency (commercial vs. light traffic). Material compatibility is crucial; using stainless steel hardware with stainless steel clamps prevents galvanic corrosion. All components, especially clamps and pivots, must be compatible with the glass thickness and the hole-drilling pattern. Furthermore, compliance with accessibility and building codes regarding opening force, maneuvering clearances, and safety is non-negotiable.

In conclusion, the flawless operation of a heavy glass door is a testament to the precision and strength of its hidden control hardware. From the powerhouse floor spring buried in the floor to the elegant stainless steel handle, each component—the guiding top pivot, the securing clamps, and the locking center or floor lock—plays an indispensable role. This integrated system transforms a fragile pane of glass into a durable, safe, and functional architectural element. Specifying these components is not merely a hardware selection but an exercise in engineering an invisible, reliable mechanism for daily human interaction.